A Strong, Stretchy, And Sticky Band-Aid For The Heart

12:09 minutes

The heart is an impressive organ that has to beat constantly for years. But what happens when heart tissue is damaged? Or when cartilage in joints like our knees wears out? These constantly moving tissues don’t regenerate easily, and there aren’t a lot of great treatment options.

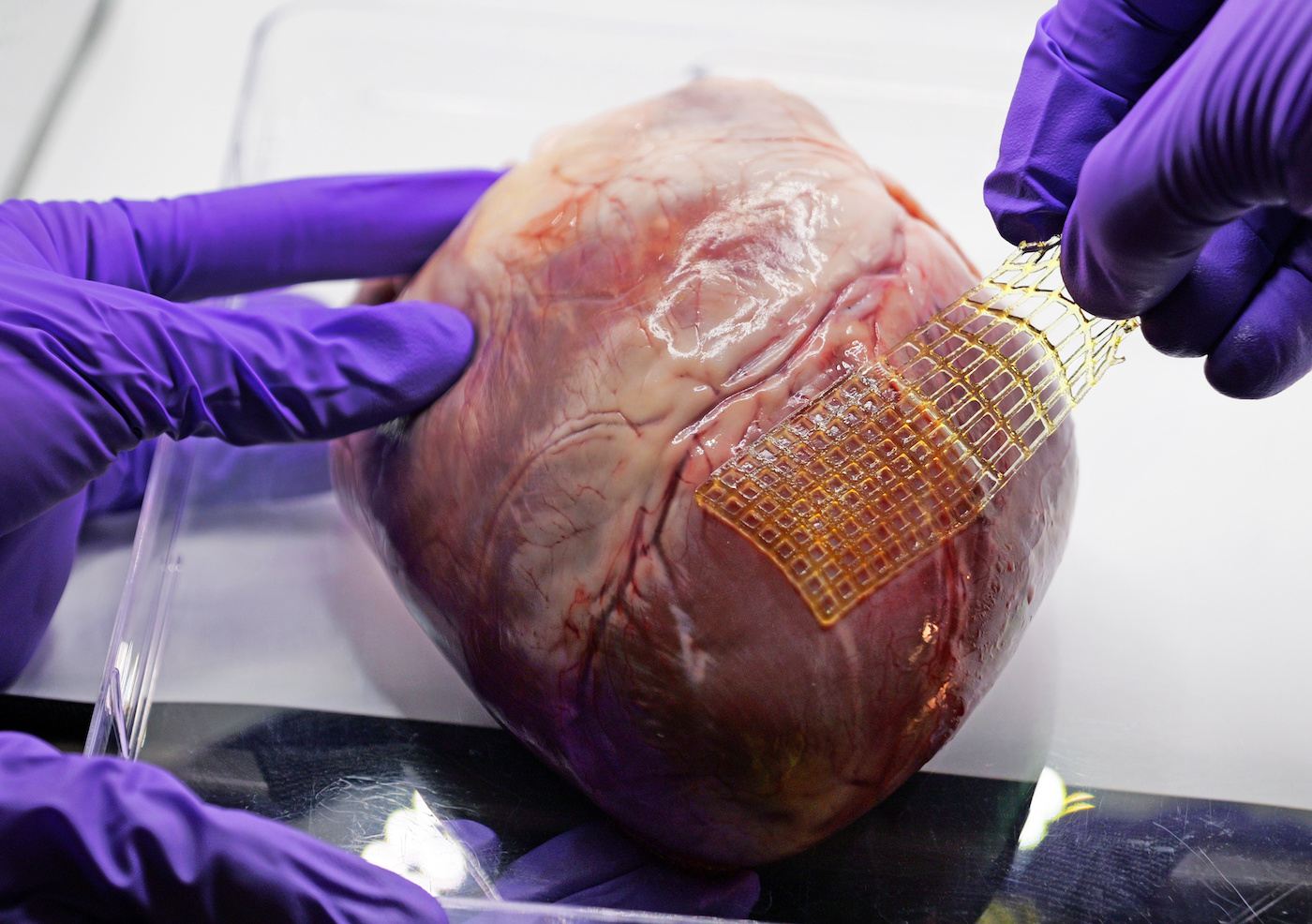

To address these kinds of problems, a team at University of Colorado Boulder invented a new strong, stretchy, and sticky hydrogel material that could act as a Band-Aid to heart or tissue lesions. They were inspired by masses of worms that tangle and untangle themselves, behaving almost as both a solid and liquid. The team was able to replicate that in a molecular structure with the help of a new 3D-printing technique. And it could have applications far beyond medicine, including for manufacturing and improving the 3D-printing process itself. Their research was published in the journal Science, and their lab has filed for a provisional patent for the material.

Dr. Jason Burdick, professor of chemical and biological engineering at CU Boulder’s BioFrontiers Institute, joins Ira Flatow to talk about the new material and how it could improve future tissue and cartilage treatment.

Dr. Jason Burdick is a professor of Chemical and Biological Engineering in the BioFrontiers Institute of the University of Colorado, Boulder in Boulder, Colorado.

IRA FLATOW: This is Science Friday. I’m Ira Flatow. A bit later in the hour, a look at the gut microbiome’s role in handling stress. And as we look ahead to the elections, the science of measuring and shifting public opinion.

But first, there are parts of our bodies that are in constant motion, right? Like your heart or your cartilage joints, your knees, your hips, your elbows. And these parts can wear out or become damaged. Tell me about that.

Well, this constantly moving tissue doesn’t regenerate easily, and there aren’t a lot of great treatment options. But a team at the University of Colorado Boulder has invented a new, strong, stretchy, and sticky material that might be able to act as a Band-Aid to the heart or tissue lesions. And it could have applications far beyond medicine.

Dr. Jason Burdick is professor of chemical and biological engineering at CU Boulder’s BioFrontiers Institute. His team, Sticky Material, research was published in the journal Science. Dr. Burdick, welcome to Science Friday.

JASON BURDICK: Great. Thanks for having me.

IRA FLATOW: All right. Before we get into the research itself, tell me about the need for this kind of material.

JASON BURDICK: Yeah, there’s so many applications where new materials are needed to treat different injuries or diseases in the body. So my lab is particularly interested in things like the heart and the joints, so dynamic tissues that have a lot of loading on them.

And so imagine that you have a defect in your cartilage due to some traumatic injury. If you just leave that alone, you’re going to end up with things like osteoarthritis. Or if you have a heart attack, you’re going to have damage to that tissue, and it just won’t pump like it needs to. And so we’re really trying to develop new therapies to help these patients that don’t really have current options.

IRA FLATOW: So you would use the tissue– let’s say, in the heart– in what way?

JASON BURDICK: Yeah, so biomaterials can be maybe implanted, for example, as a patch on the surface of the heart. So once your heart is damaged through something like a heart attack, there’s a lot of things that happen biologically.

And sometimes you can restrain it through a biomaterial, or you could deliver drugs or therapeutics, like cells, using biomaterials. And so we’re looking for those types of situations where we can implant a material to then hopefully help patient outcomes.

IRA FLATOW: And presently, the treatments are what if you have a heart lesion?

JASON BURDICK: Yeah, there’s very little right now. So, lots being explored, many examples of things like stem cells delivered to the heart. But right now, we try to, one, prevent a heart attack from happening by improving things like patient health. And then we give them some drug therapeutics, and we try to restore blood flow to the heart as quickly as possible.

But if the heart attack is so damaging that there’s no treatment available, it’ll just kind of slowly go on to things like heart failure. So it’s those patients that we’re looking at trying to help.

IRA FLATOW: And people who have joint problems– ACL tears or arthritis– can this help them also?

JASON BURDICK: Yeah, we hope so. It’s kind of the same idea. So, like, the heart, cartilage doesn’t have some sort of natural way for it to regenerate itself, so we need therapeutics. So, right now in the joint, if you can do things early on after damage, you can prevent some things from occurring long-term.

So we’re trying to help those patients that have some damage to prevent the onset of things like osteoarthritis and the need eventually for something like a total joint replacement. So if we can implant materials that can maybe help grow new tissue, hopefully those patients have a better outcome.

IRA FLATOW: OK, so much for the wind-up. Now let’s go to the pitch. [LAUGHS]

JASON BURDICK: All right.

IRA FLATOW: What was your big breakthrough here in creating this material? And tell us what it is.

JASON BURDICK: Yeah, the invention, I think, is really a new way to process materials. So we’re looking at 3D printing techniques. And so this is the way that we can build up materials of any, really, shape or structure by applying materials maybe layer by layer with controlled positioning. So that was really the technology that we wanted to use.

But over many years, we were disappointed with the material properties of those materials that we were 3D printing. So we kind of had to step back and think about the material design. And so this is where we got excited about this idea of how molecules entangle together, and it’s that entanglement that then leads to improved properties. So we want things that are really tough so you can apply load on it, stretch it, squish it. And eventually, they can then bear that load without failing.

IRA FLATOW: Hmm, and the structure for this tough hydrogel is unique. I understand that your team was inspired by worms, right?

JASON BURDICK: Yeah, let me talk about these worm blobs.

IRA FLATOW: [LAUGHS]

JASON BURDICK: In many years, there’s been some interest in the polymer physics community of thinking about how molecules– so polymers are just these long molecules– and how they entangle together. And often, we look to the environment around us and how organisms interact.

And so on a much larger scale, if you think about worms, a single worm is going to behave in one way. But if you gather lots of these worms together into what’s called a worm blob– and they do this naturally. It’s kind of a protective mechanism to respond to things like temperature and light. So this really, then, leads to a collective behavior of these worms, these kind of entangled structures.

And so at this molecular level– so shrink this kind of phenomenon down to molecules. So if we can entangle them together, then they will behave differently when we load them. So in our case, we want these polymers to slide past each other. So if we just lock them all together, if we apply a load to it, it would just fail if we apply a load. But with these entanglements, they start to slip and slide past each other when you apply a load. And that really gives us a lot of these interesting properties like toughness.

IRA FLATOW: So it’s like a blob of worms repeatedly tangling and untangling itself.

JASON BURDICK: That’s right.

IRA FLATOW: So if you have like a squishy solid and a liquid when you need to have it.

JASON BURDICK: That’s exactly right. So yeah, they kind of behave like a liquid or a solid under different conditions, just like our materials.

IRA FLATOW: That is cool. And you were able to replicate this structure in a 3D printer?

JASON BURDICK: That’s right. So this is really work by a fantastic graduate student, Abhishek Dhand, and a great research associate in my lab, Matt Davidson. They took this idea, and they looked at what others had done to make polymers entangled.

Unfortunately, there was this kind of incompatibility with how we 3D print, which means really fast reactions, and how people had made entangled polymers, which are really slow reactions. And you want them to grow slowly so that they build those entanglements. So there’s this mismatch.

And so what Abhishek and Matt had then really developed is a way to do both. So our idea was that on the 3D printer, then we use light to design the object, but then we use this slow, secondary reaction to increase, then, that entanglement over time. So it was just a new idea about how we process materials that then gives rise to these new, interesting properties, as well as the ability to 3D print any shape, any structure.

IRA FLATOW: And for our listeners, describe for us what does this material look like? Can you hold it in your hand? Is it like a accordion? Is it like a stretchy, holey thing, like Swiss cheese?

JASON BURDICK: Yeah, so the 3D printing lets us really design it of any structure, but you think of it just kind of as a solid, kind of plastic material. These are hydrogels, which means that they have a water content to them. So you think like a contact lens, but a contact lens is going to break if you pull on it. These are really strong materials.

But depending on the application, if we want to make a patch, often we’ll print it within a lattice structure, so a bunch of holes in it so it’ll conform well to the tissue surface. If we want to make a scaffold to repair cartilage, we’ll put a lot of porosity into it. So we can really make it into any shape that we want. But it’s a stretchy material that you can really stretch many times its length without it failing.

IRA FLATOW: Well, now that you have the material, has anybody actually tried to apply it to these things, these techniques that we’re talking about, the uses?

JASON BURDICK: Yeah, we’ve started to. One area that we were excited about was the idea of adhesive materials. So if you think about a material that goes on to the heart, you want it to stick to it or attach because we want it to stay there to provide that function. And so most materials, you would just put it on the heart, and it would just fall off.

So we were excited to think about making it adhesive by changing the molecules at that interface between the material and the tissue, which can guide that adhesion. And again, if you think of a heart beating, if you didn’t have a material that was stretchy and could respond to that beating, it would just fall off.

Same as the joint– if you load it, and it is too rigid or too soft, it’s going to fall off. So that’s where these material properties are really important. So we’re starting to apply it to some of these different applications in both cardiovascular and musculoskeletal systems.

IRA FLATOW: So has anybody been using it yet in tests on people?

JASON BURDICK: No, we’re very early on that. We’ve actually founded a startup company that’s exploring it to make patches that would go on your disk in your back. So if you’ve had a surgery, could you actually apply this system as an adhesive to prevent things like re-herniation? So early stages on that, definitely doing the early studies on tissues, and then, slowly, it will move towards patient applications.

IRA FLATOW: Well, our listeners are going to be happy to hear about– everybody has back pain or some sort of back injury.

JASON BURDICK: Yeah, very relatable. Very relatable.

IRA FLATOW: Very relatable. I heard a student of yours did a kind of informal test to see how strong it was. Tell me about that.

JASON BURDICK: Yeah, that’s right. Usually, in the laboratory, we make these really defined shapes, and we stretch it on an instrument so we can get the quantitative values for things like material properties. But we live in Boulder, Colorado. Everyone’s out on their bikes.

And so one of my research associates, Meg Cook, she just took one of these that we had printed and just kind of ran it over on her bike. And you see it squish down, and then it just recovers. So if it can withstand the load of a bike in Boulder, Colorado, hopefully it can withstand some of these loadings on tissues.

IRA FLATOW: Well, if you’re going to run over it with a bike, I’m thinking there’s got to be other uses for it outside of the body, right?

JASON BURDICK: That’s right. Yeah, because, again, the invention is really the method to 3D print and trying to improve these properties. So we see lots of applications. So 3D printing and the types of technology that we’re using has really also transferred into the manufacturing space. So any time you want to make something with specific structures, custom parts, precision components, 3D printing is a great way to do that.

And right now, they use technologies like exposing these printed materials to a lot of heat, a lot of light, to then improve its properties. Our technique kind of avoids that. It inherently can improve the properties just through the way we make these materials. So we see lots of value towards non-medical applications as well.

IRA FLATOW: So to use it, then, people would just buy the squishy stuff, put it in their 3D printer, and then print what they’d like.

JASON BURDICK: Yeah, you develop maybe a new resin, which is the precursor. So if people are familiar with 3D printing, usually, you start with a resin or an ink. So you’d buy that with the right components to it, put it on your 3D printer, and then you’d be able to have these types of properties.

IRA FLATOW: All right, so when can I buy this stuff for my 3D printer?

JASON BURDICK: Well, hopefully, the company does well, and we can start to manufacture this, of course, raising funds and such. But this, especially in the manufacturing space, could be something that’s useful within a year or two.

IRA FLATOW: Hmm.

JASON BURDICK: The biomedical space always takes a longer time because you have to do the right test to develop it for a specific application. But yeah, we hope this technology makes an impact very soon.

IRA FLATOW: Sounds terrific. Thank you for taking the time to be with us today, Dr. Burdick.

JASON BURDICK: Yeah, thank you so much, Ira.

IRA FLATOW: Dr. Jason Burdick, professor of chemical and biological engineering at the University of Colorado in Boulder. And if you want to see images of this material in action– it’s pretty cool– head over to our website at sciencefriday.com/printed, sciencefriday.com/printed.

Copyright © 2024 Science Friday Initiative. All rights reserved. Science Friday transcripts are produced on a tight deadline by 3Play Media. Fidelity to the original aired/published audio or video file might vary, and text might be updated or amended in the future. For the authoritative record of Science Friday’s programming, please visit the original aired/published recording. For terms of use and more information, visit our policies pages at http://www.sciencefriday.com/about/policies/

Dee Peterschmidt is a producer, host of the podcast Universe of Art, and composes music for Science Friday’s podcasts. Their D&D character is a clumsy bard named Chip Chap Chopman.

Ira Flatow is the founder and host of Science Friday. His green thumb has revived many an office plant at death’s door.